English

Request a Technical Diagnosis

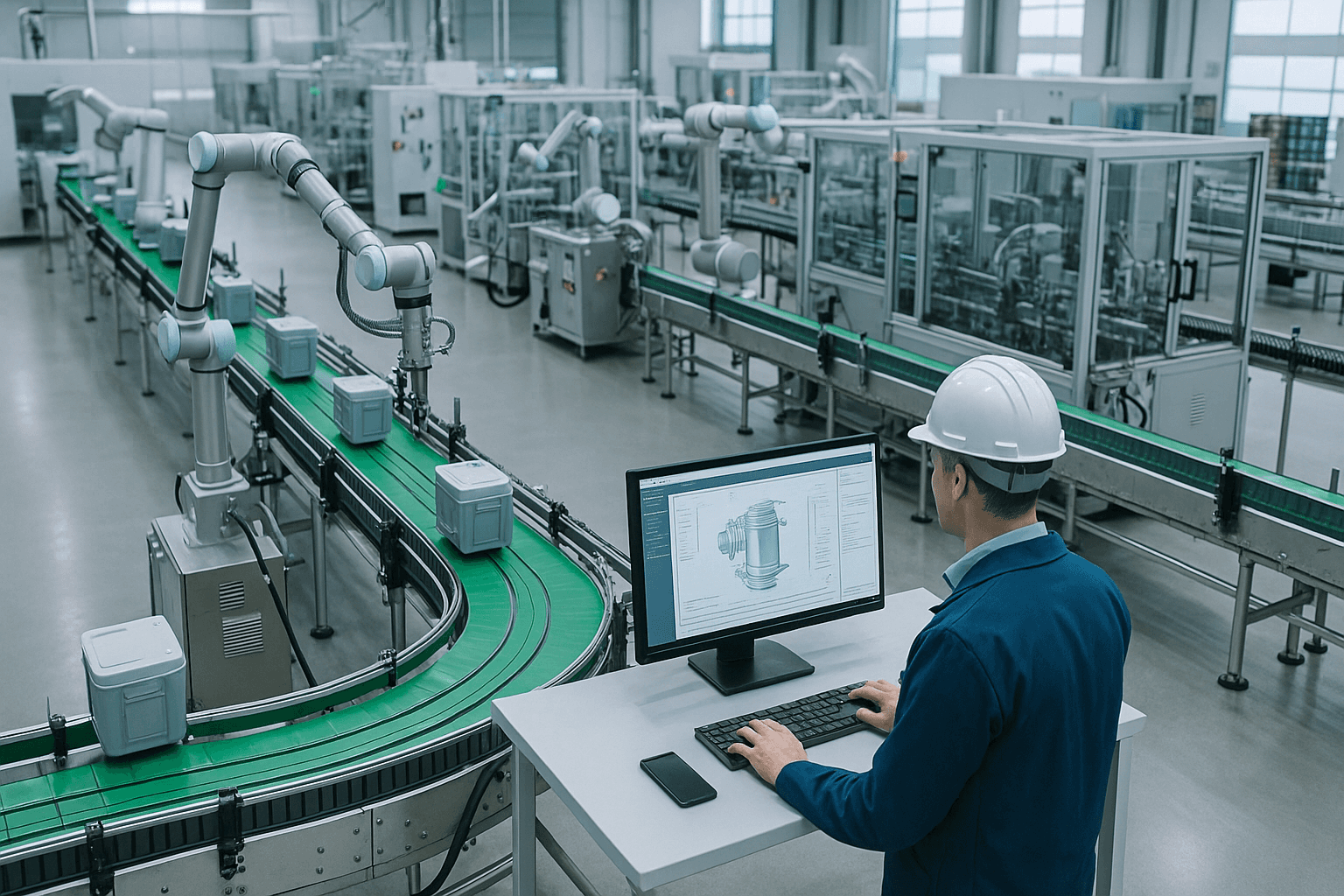

At Innovx, we transform complexity into confidence. With reliable data, agile implementation,

and comprehensive solutions, we help make every process more efficient and every decision more secure.

Innovation

and Technology

Innovative solutions that optimize production, increase efficiency, and ensure competitiveness

in the market.

Simplification

and Practicality

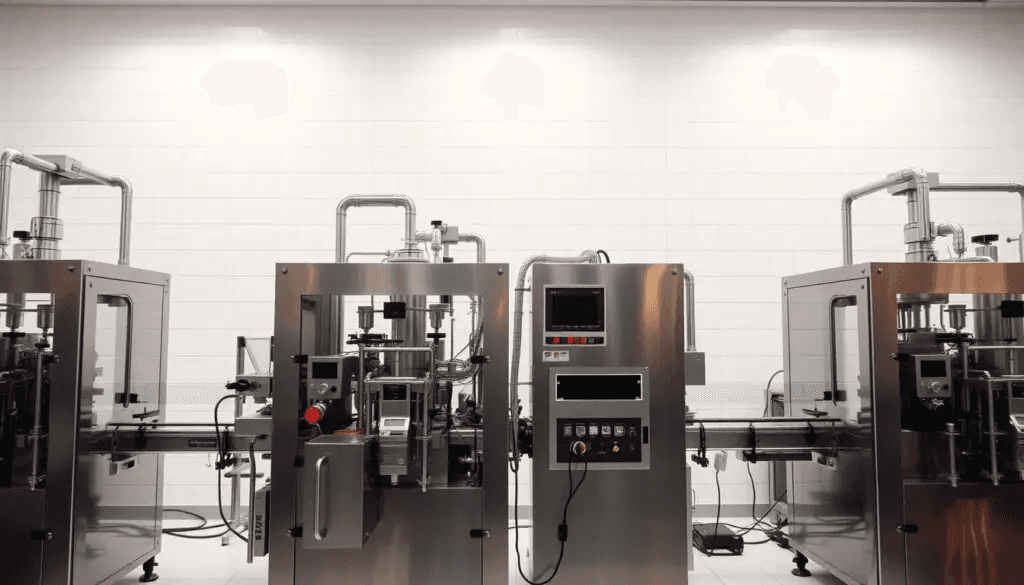

Intuitive and easily integrated solutions that demystify automation and make processes simpler and more efficient.

Specialized Technical Support

Qualified engineering team to provide technical support, consulting, and maintenance services.

Quality

and Reliability

Commitment to excellence in every detail, from components to final delivery. We ensure precision, durability, and reliable results in all products and services.

We are a company specialized in solutions for process control and quality improvement in production lines. We manufacture, distribute, and provide support for high-performance equipment, always focusing on precision, reliability, and added technical value. Our team consists of specialists committed to excellence from project inception to maintenance.

Clients and Partners

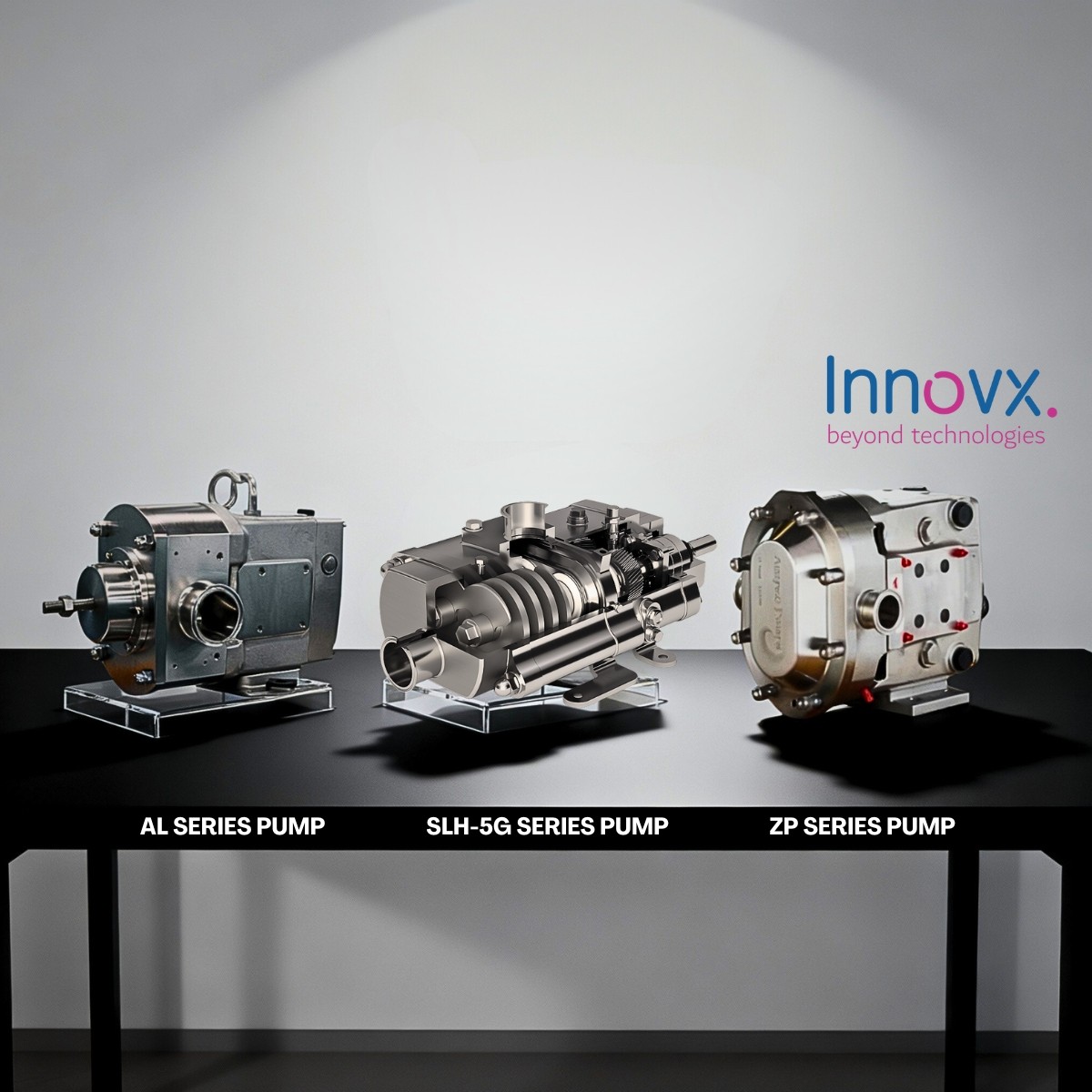

Applications:

• Hygienic transfer of milk and dairy products

• Mixing of ingredients (yogurts, cheeses)

• Automated CIP (Cleaning in Place)

• Product interface control

Applications:

• Pumping of viscous products (sauces, …)

• Recipe homogenization

• Mixing of solid/liquid ingredients

• Processes with strict sanitary control

Applications:

Delicate Wine Filtration and Transfer

CO₂ Control in Sparkling Wines

Mobility Between Tanks

Line and Tank Cleaning

Applications:

• Smart Sensors for filling lines

• Uligh Samplers and Agitator for TPO and CO2

• Automated tank cleaning (CIP)

• Sanitary transfer and filling

Applications:

• Carbonation control

• Real-time CO₂ measurement

• Mixing of concentrates with water

• Filling line and quality

Applications:

• Transfer of sensitive chemical products

• Formula homogenization

• Measurement and control of industrial gases

• Automated cleaning and sterilization

OEMs

Applications:

Pressure, force, and impact measurement

Integration of sensors and instruments

Turnkey solutions for end customers

Modularization of lines and industrial automation

Applications:

• In-line pressure, force, and impact measurement

• In-line parameter measurement (pH, CO₂, ...)

• End-of-line quality control

• Mobility and flexibility in production

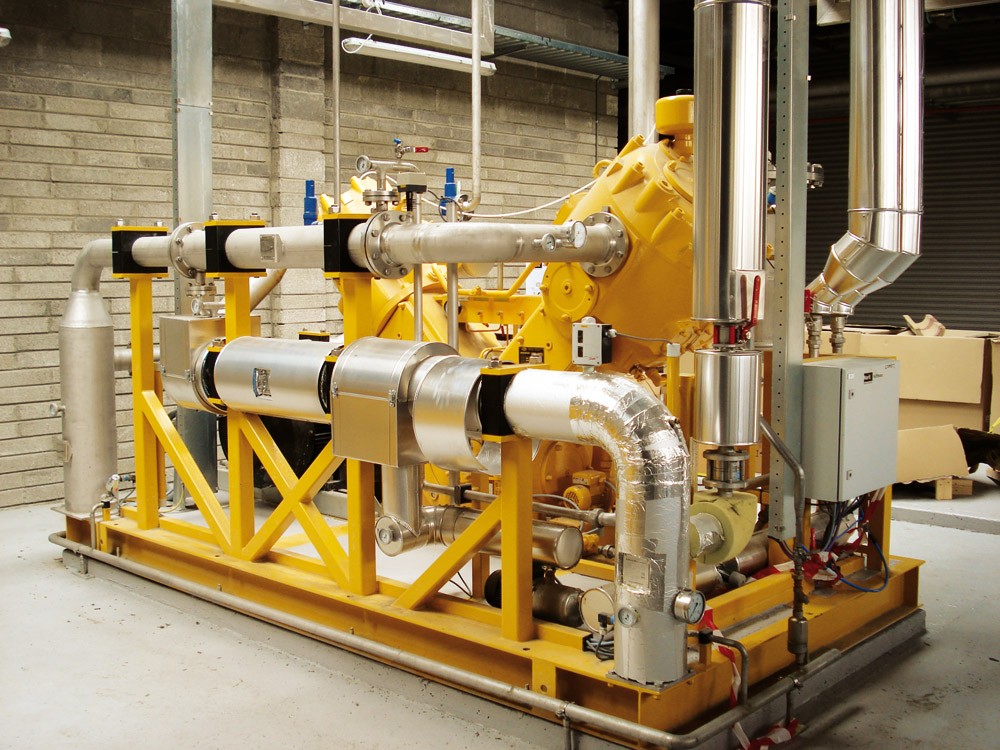

CO₂ Plants

Applications:

• CO2 purity and contaminant analysis service

• Flow and pressure control in gasification processes

• Operational safety and traceability

We have the necessary experience to handle the most demanding

technical specifications for your projects and products.

Industrial Systems for

Mixing and HomogenizingView products

Process

ControlView products

Quality

AnalysisView products

Gas Analysis and

Control SystemsView products

Contact us

They ensure precision, efficiency, and safety in industrial processes with customized solutions, sanitary design, and easy integration. All of this comes with high reliability, reduced losses, and close, specialized technical support.

01

Continuous process control for immediate decision-making.

02

03

04

05

06