Quality Analysis

Our quality analysis products ensure precision, reliability, and total control at every stage of the process.

Voyager

The VGR-LOAD line from Voyager controls the applied load with both static and dynamic versions. In static mode, it directly calibrates the load, whereas in dynamic mode, it simulates the actual process, recording the load values in real-time without interrupting production.

With visual and traceable reports, VGR-LOAD allows

identification of force variations, prevention of failures, and ensures the quality standards required by the market, transforming adjustments into a technical and precise process.

Prevents can dents and glass breakage.

Standardization of applied force in real time.

Precise calibration of seamers and cappers.

The Voyager VGR-PRESSURE line offers two complementary solutions: the dynamic model, which travels along the line and records the pressure in real-time, and the VGR-PRESSURE IMPACK model, which allows puncturing already filled packages and measuring the internal pressure, including in pasteurizers.

The measurements provide precise diagnostics, allowing immediate adjustments on the line, which reduces waste, increases efficiency, and ensures complete traceability of the process.

Precise control of internal pressure in real time.

Prevention of vacuum failures or nitrogen injection.

Pressure and temperature stability in the pasteurizer.

The VGR-IMPACT from the Voyager line was developed to directly address these critical points. Integrated into the production line flow, it simulates a real bottle and measures impacts in real-time using IPS (Inches per Second) or G-forces, generating precise and easily interpretable visual reports.

Internal studies indicate that an increase of just 5 IPS in certain sections of the line can multiply the number of bottle breakages by five, even while remaining within the manufacturer's certification limit. This demonstrates that precise and continuous control of impacts is essential to reduce losses and enhance operational efficiency.

Optimization of internal packaging transportation.

Immediate reduction of breakage losses.

Continuous improvement in bottling, labeling, and pasteurization lines.

The VGR-FORCE provides a unique solution for accurately measuring and monitoring the force applied to packaging during the production process. The device is integrated into the production line, performing real-time measurements as it moves along the line, enabling detailed and continuous control of the applied force.

With the measurements taken, it is possible to identify variations and make immediate adjustments, resulting in reduced losses and increased process efficiency.

Precise monitoring during transport.

Advanced sensors and gyroscope.

Integration with the "Voyager Connect" app.

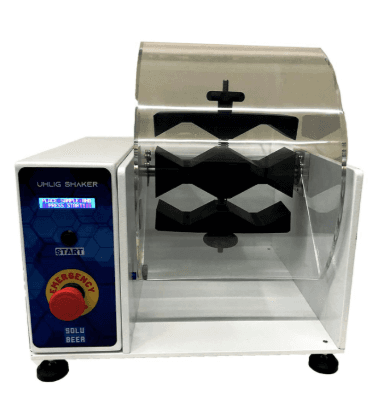

The Uhlig Shaker is a device used for measurements of TPO (total package oxygen) in beverages, utilizing the Uhlig method. It shakes up to 4 samples simultaneously at 40 rpm, ensuring standardized and precise preparation for residual oxygen analysis.

Low maintenance.

Reduction in product losses.

Low-cost investment.

Lower workload volume.

All sizes of bottles/cans.

The SIBA – In-Line Brewer Analyzer is a technology developed by Spectramatics to monitor brewing processes in real time, directly on the production line. Installed in the mash tun or cereal cooker, this analyzer provides continuous and precise analytical data on the composition of the wort, without the need to collect samples.

Continuous and real-time monitoring of the brewing process.

Direct control of production, without delays due to laboratory analyses.

Greater predictability of fermentation, even with variations in raw materials.

Assists the brewmaster in optimizing yield and maintaining consistent quality.

Prevents late reactions and blind decisions, provides actionable data instantly.

ZYMON is a real-time inline analyzer designed to monitor fermentation and optimize process efficiency. By providing continuous data on sugar consumption, yield, and fermentation health, ZYMON helps producers maximize production, reduce downtime, and ensure consistent results.

Early detection of process deviations, allowing for quick and effective interventions.

Easy integration with control and industrial automation systems.

Reduction of operational costs through automatic adjustments based on real-time data.

Increase in batch consistency, ensuring greater predictability in production.

Improvement in the quality of the final product by preventing incomplete or contaminated fermentations.

Gas Analyzers

This system was designed to ensure highly reliable and precise CO₂ sampling, transforming liquid CO₂ into gas in a controlled manner for rigorous laboratory analyses.

Converts liquid CO2 into gas in a controlled and

stable manner through flash vaporization.

Provides a sample with constant pressure and flow for

laboratory analysis.

Recommended for sampling from tanks, trucks, railway wagons, or cylinders.

Ideal for purity, impurity, and moisture analyses.

Compliant with ISBT, EIGA, and USP standards.

Ensures stable delivery to the analytical system.

This equipment was designed to convert liquid CO₂ into dry ice quickly, controlled, and completely safely, providing an efficient solution for sensory tests of taste, odor, and purity.

Converts liquid CO2 into dry ice snow quickly and in a controlled manner.

Ideal for sensory tests of taste, odor, and gas purity.

Direct connection with storage tanks, without

manual effort.

Hands-free operation, safer and more hygienic.

Compact and portable design, easy to install.

No gas waste and with stable performance.

Would you like to learn about the solutions that Innovx can provide to optimize and automate your industry's processes?

Contact us