Process Control

Transfer low or high viscosity liquids with

maximum hygiene, precision, and easy maintenance, without

compromising performance or halting production.

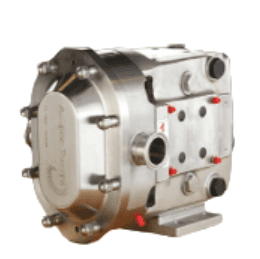

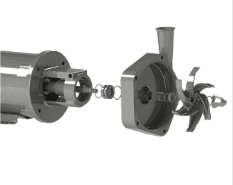

The ZP series is designed for those who require maximum versatility, whether for low or high viscosity products, sensitive liquids, or aseptic processes. With over 50 models and 3A/EHEDG certifications, these circumferential piston pumps stand out for their patented front-loading seal design, which allows seals to be replaced without disassembling the piping.

Versatile: for low and high viscosity.

Easy maintenance: front seal without disassembly.

Effective CIP (ZP3): cleaning without performance loss.

Durable: 100% stainless steel construction (304 / 17-4).

Wide range: over 50 models, including aseptic versions.

Certified: 3A and EHEDG throughout the line.

Excellent cost-effectiveness with reliable performance.

High flexibility for different products and processes.

Easy and quick maintenance, with reduced downtime.

Hygienic and safe design, ideal for demanding environments.

Complete customization to adapt to each application.

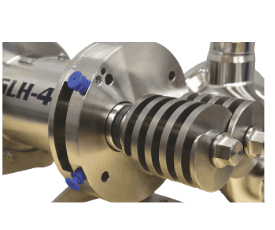

With Bornemann twin-screw technology, this positive displacement sanitary pump gently moves the product, almost without pulsations, from suction to discharge.

Pulsation-free pumping: ideal for sensitive products.

High capacity: handles viscosities up to 1,000,000 cP and particles up to 58 mm.

True CIP: cleaning in place without an additional pump.

Robust performance: up to 25 bar and 1300 GPM (300 m3/h).

Facilitated maintenance: screw replacement without disassembling motor or draining oil.

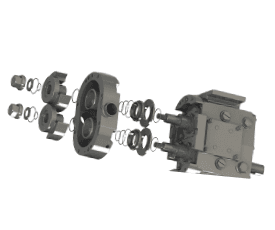

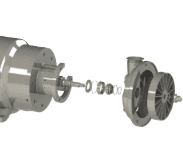

The major advantage of AC+ lies in its innovative shaft, which eliminates the traditional impeller pin. This reduces vibration, increases stability, and extends the seal's lifespan. The smart design also simplifies assembly and makes cleaning more efficient, ensuring sanitary performance with less maintenance effort.

Reliability without surprises: fewer failures, less maintenance, and more production.

Real cost-effectiveness: premium model performance at a fair price.

Guaranteed sanitary safety: ideal for food, beverages, dairy products, and cosmetics.

Centrifugal pumps

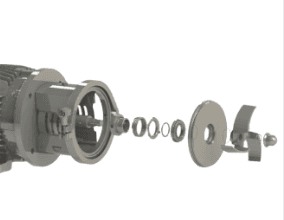

The L Series are high-efficiency centrifugal pumps made of stainless steel, used to transfer liquids smoothly, safely, and hygienically in demanding industrial environments such as food, beverage, cosmetics, and pharmaceutical factories.

Reliability: high-quality materials and robust construction enhance durability and reduce downtime.

Hygiene and Safety: fully compatible with CIP and sanitary certifications (3A), ideal for industries with strict standards.

Efficiency: balanced impellers and optimized design result in lower energy consumption and higher output.

Ease of Integration: direct replacement of pumps from other brands without complications.

Tailor-made Customization: from electropolishing to adaptations for sterile pharmaceutical applications.

Long-term Cost Reduction: less wear and tear, longer seal life, less maintenance.

The M Series is a robust and versatile centrifugal pump, designed to efficiently and safely transfer liquids, even under extreme conditions, including hot oil above 200°C when adapted for this purpose. It can be used in sanitary processes (such as water, juices, dairy) or more demanding industrial applications, thanks to its reinforced construction and flexibility in sealing options.

Total Versatility: a single pump for multiple functions and sectors, from a juice line to an industrial process with hot oil.

Above-average Durability: ideal for those who cannot afford to stop due to wear, heat, or sealing failures.

Guaranteed Sanitary Safety with 3A Certification.

Easy Customization: choose the finish, type of seal, and adapt as needed.

Fast Delivery and American Reliability, manufactured and assembled in the USA.

The SP Series is a liquid ring self-priming pump, specifically designed to handle liquids mixed with air. Even when there is air or gas within the product, the SP continues to operate efficiently, quietly, and steadily, without compromising the integrity of the line.

Operational tranquility: operates even with air in the system.

Consistent performance in critical applications, such as CIP return.

Self-priming: initiates flow without manual intervention.

Robust design and balanced impeller: reduces wear and maintenance.

High reliability in shear-sensitive products.

Premium construction in 316L stainless steel with strict tolerances.

Compatible with hygienic environments and industrial lines.

Capacity up to 275 GPM, 10 BAR, and 1200 cP viscosity.

Manufactured in the USA, with fast delivery and dedicated technical support.

The SKR is a pump specially developed to transfer yeast continuously, smoothly, and efficiently, ensuring that the cells maintain their vitality during the process. Unlike generic equipment, which can damage or stress the yeast, the SKR respects the sensitive nature of this vital ingredient.

Confidence in the fermentation process: yeasts arrive intact and active at their destination.

Higher yield and consistency of the final product.

Lower input loss: efficiency up to 13 m3/h, even with viscous fluids.

More predictable, clean, and controlled process.

The ROLEC DH is a portable and secure system designed for dry hopping, which involves adding hops (or other ingredients such as fruits, spices, coffee) to the beer during fermentation without opening the tank and without the risk of oxidation. Instead of climbing a dangerous ladder to pour hops at the top of the fermenter, the brewer can perform the entire process at ground level, ensuring superior safety, control, and efficiency.

Mobility and simplicity: complete and portable system, ready to use.

Compatible with CIP, no additional pump required.

Made of stainless steel 304 and 316L, robust and durable.

Hop induction in a closed circuit, without oxygenation.

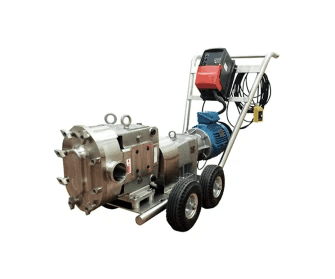

The Wine and Must Cart is a portable transfer platform equipped with a Series ZP1 positive displacement pump, designed to gently, efficiently, and safely move sensitive liquids such as wine, must, and juice without contamination or oxidation. It is constructed to withstand demanding environments (both in the cellar and outdoors) with materials of the highest sanitary durability.

Complete protection of wine or juice quality during each transfer.

Peace of mind when operating in any environment, without fear of rust or failures.

Equipment that is easy to move, hygienic, and durable - a true work partner.

Tailored customization, adapting to different stages of winemaking: barrels, filtering, bottling.

304 stainless steel gearbox - zero corrosion, high durability.

The Wine Cellar Cart is a portable and robust solution for pumping liquids in tight production environments such as cellars, breweries, or process laboratories. It functions as a mobile centrifugal pump, ideal for liquid transfer or CIP cleaning, offering high performance with maximum mobility.

Total mobility with lightweight and durable construction, ideal for confined spaces.

Total sanitary compliance, with corrosion-resistant materials and hygienic design.

High reliability with reduced maintenance, thanks to the balanced impeller and durable sealing.

Operational versatility: a single pump that serves for CIP, transfer, knockout, and whirlpool.

Would you like to learn about the solutions that Innovx can provide to optimize and automate your industry's processes?

Contact us